×

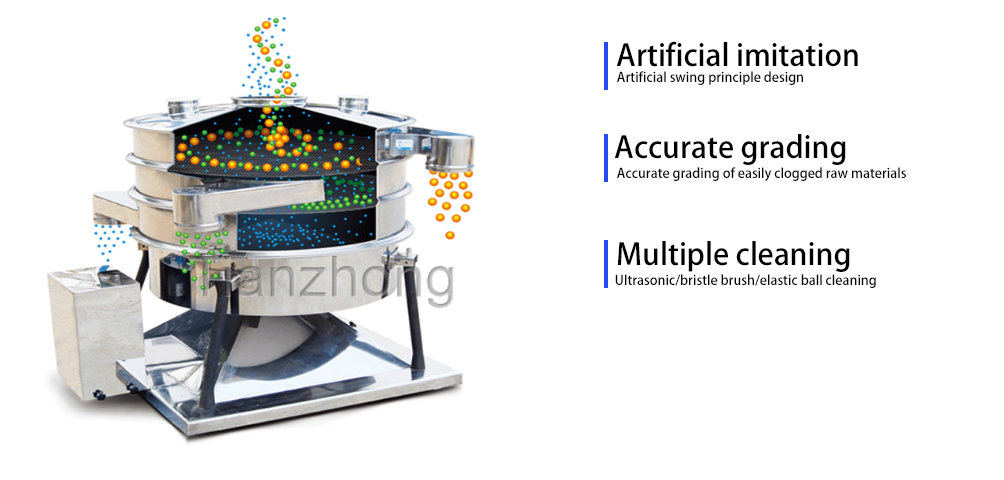

The two-layer circular swing screen is a highly efficient screening machine specially designed to meet the needs of manufacturers requiring high-volume, high-precision screening. The simplest form of screening involves using both eyes to observe while manually sifting with both hands. The circular swing screen is a mechanical simulation of this process, effectively replicating the principles of manual screening motion. It is suitable for all types of fine and ultra-fine powders and granular materials, particularly those that are difficult to handle.

Up to 5 times higher output per unit area. Precise to six levels of separation, with a screening efficiency of up to 90-95%.

The use of silicone rubber balls, ultrasonic waves, and other highly efficient screen cleaning devices ensures that the screen holes will not become clogged.

Closed dust removal, safe operation.

Acceleration is 4.5 times lower than that of a vibrating screen, resulting in longer screening part life and reduced maintenance; noise level is less than 75 decibels.

Optimised structural balance, low dynamic load on the foundation.

1. The basic rotational motion is similar to manual screening. The eccentricity is adjustable from 25 to 40 mm, and the low-speed V-belt speed is adjustable from 120 to 360 rpm.

2. The dwell time for each product can be adjusted by altering the radial and angular orientation of the swing screen relative to the drive shaft axis.

3. This creates a three-dimensional rolling motion combining horizontal and vertical movements. Material is uniformly distributed across the entire screen surface from the centre to the outer edge, propagating axially in a spiral motion, thereby completing the screening process for fine particles.

4. Horizontal and vertical acceleration increases with particle movement, enabling particles close to the sieve aperture size are successfully separated.; larger particles are transported to the outlet, where flow is controlled by an adjustable guide device, which is another factor influencing material residence time.

5. This process is repeated between screening layers.

Chemicals, food and flavourings, plastics, mining, pharmaceuticals, wood and plywood, metallurgy, rubber, feed, fertilisers, sugar, salt, and recycling.

Henan Tianzhong Vibration Equipment Co., Ltd. integrates “research and development, production, sales and service”, with an annual production capacity of more than 5,000 units, and its products cover the three major fields of vibrating screening, conveying and lifting, and dust removal, including rotary vibrating screen, vacuum feeder, dust-free feeding station, ton bag feeding station, and customized various kinds of dust-free powder supply system, which are committed to dozens of series of dust-free powder screening and mixing one-stop solutions. The products are widely used in medicine, chemical industry, abrasives, ceramics, mining, food, metallurgy and other industries, and for a long time for the domestic more than 150 counterparts to provide OEM services, and many large-scale enterprises to establish long-term supporting cooperation. Relying on standardized CAD design and strict quality control system, our products are known for high precision and stability, and are exported to the United States, France, Russia, Australia and Southeast Asia and other countries and regions.

We are a high-tech enterprise specializing in the research, development and production of vibrating screening, conveying and lifting, crushing and mixing equipment, with products including but not limited to:

●Vacuum Feeder

●Small Bag Dust-free Feeding Station

●Ton Bag Feeding Station

●Powder Supply System

●Circular Swing Screen Series

●Vibrating Screen

We support customized production to meet the special needs of different industries.

Of course, we will design according to customer requirements.

5-10 working days for conventional products.

We have a large factory in Xinxiang, China, covering an area of 12,000 square meters. Welcome to visit!

We usually accept T/T, L/C,T/T: 30% in advance as down payment, the balance before delivery.

We provide 1-2 years warranty (depending on the model), after-sales team responds within 24 hours, support remote guidance or on-site repair.