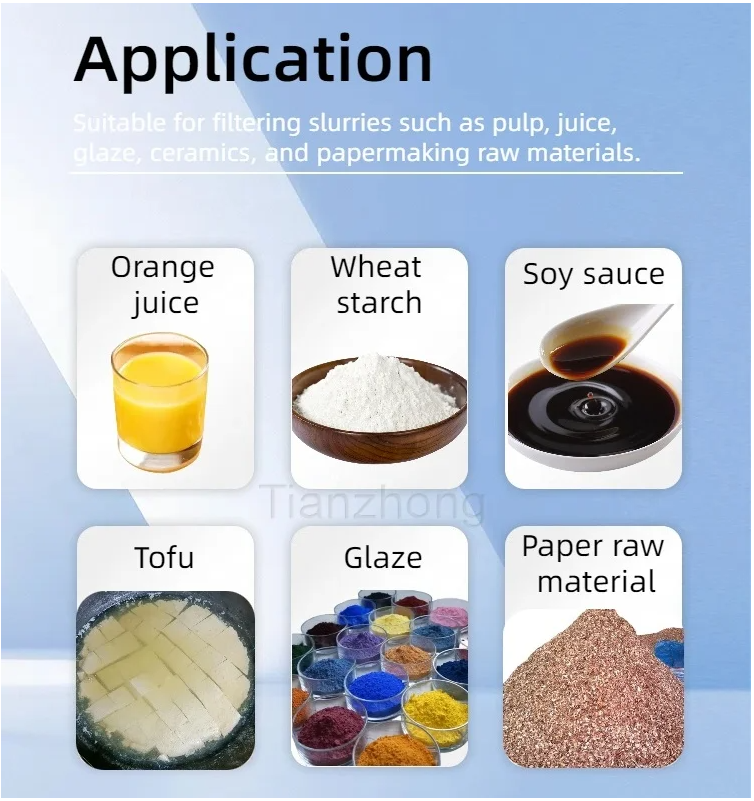

In industries such as mining, ceramics, chemicals, wastewater treatment and beverages, the efficient separation of solids from liquids within slurries and the precise classification of solid particles represent a critical and highly challenging process. Conventional vibrating screens often perform poorly when handling slurries with high moisture content, high viscosity and a tendency to clog. This is precisely where our specialised slurry screening machines excel.

Specifically engineered to handle diverse complex slurries, this product combines high efficiency, reliability and ease of maintenance. It represents the ideal solution for optimising your production processes, enhancing product quality and reducing operational costs.