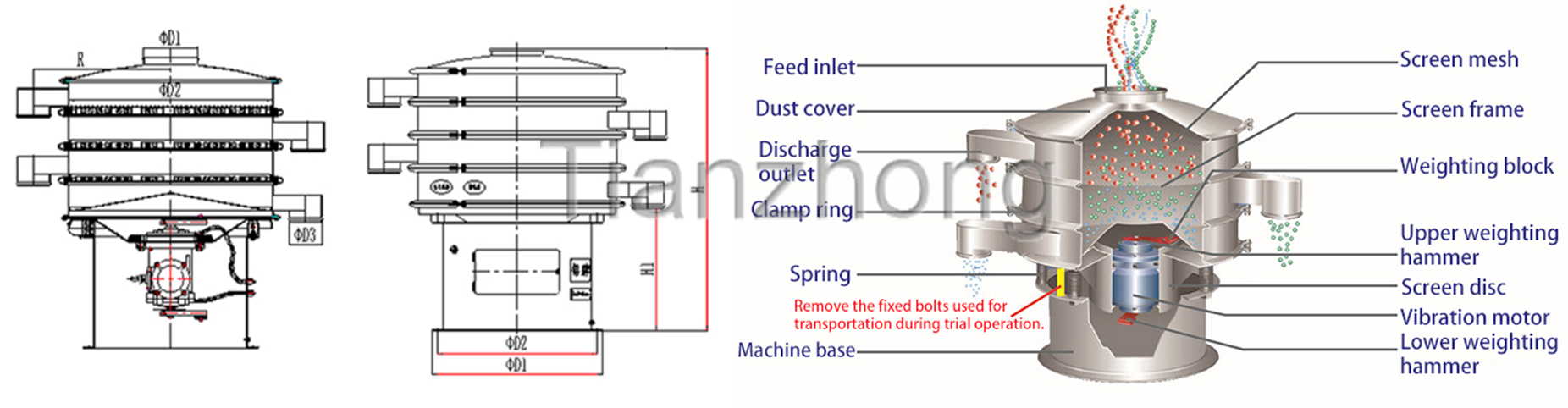

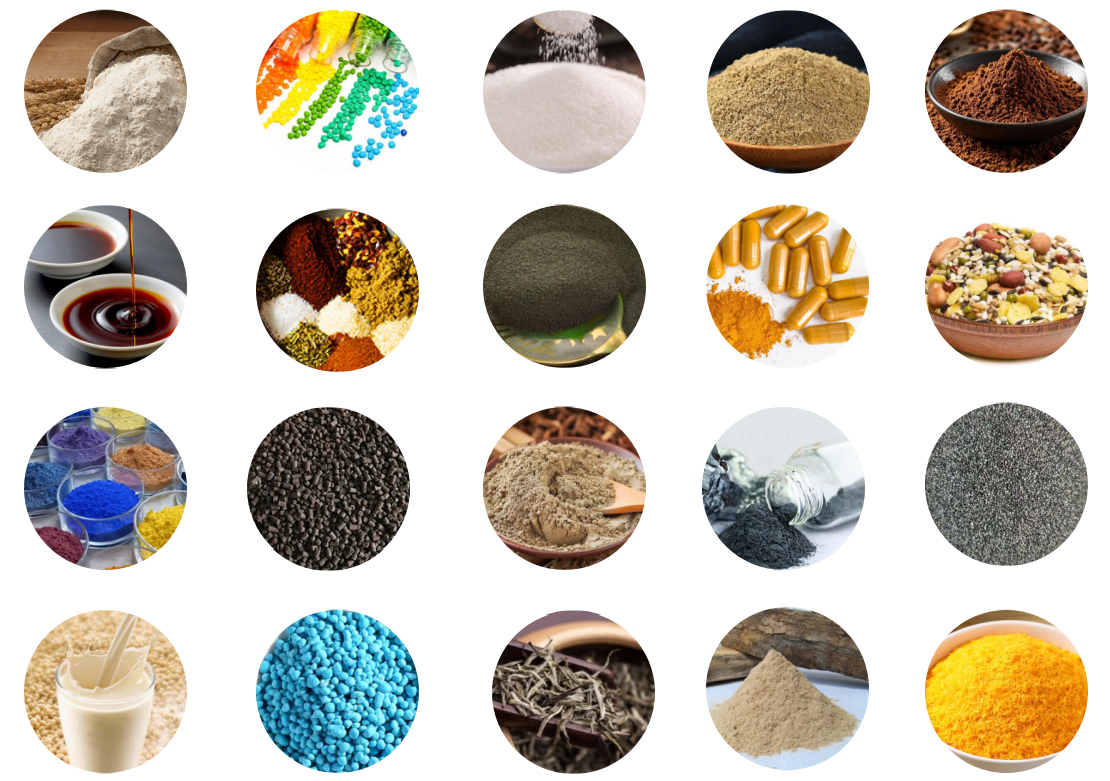

The rotary vibrating screen is a high-precision screening device that uses a vertical vibrating motor as its vibration source. It achieves efficient material classification through three-dimensional rotational vibration (a combination of horizontal, vertical, and inclined movements). Its unique motion trajectory causes the material to spread in a spiral pattern on the screen surface, significantly improving screening efficiency and accuracy. It is particularly suitable for the screening, impurity removal, and classification of fine powders and granular materials.

Based on material, they can be classified into the following three types:Contact Stainless Steel Rotary Vibrating Screen,All-Stainless Steel Rotary Vibrating Scree,All-Carbon Steel Rotary Vibrating Screen.