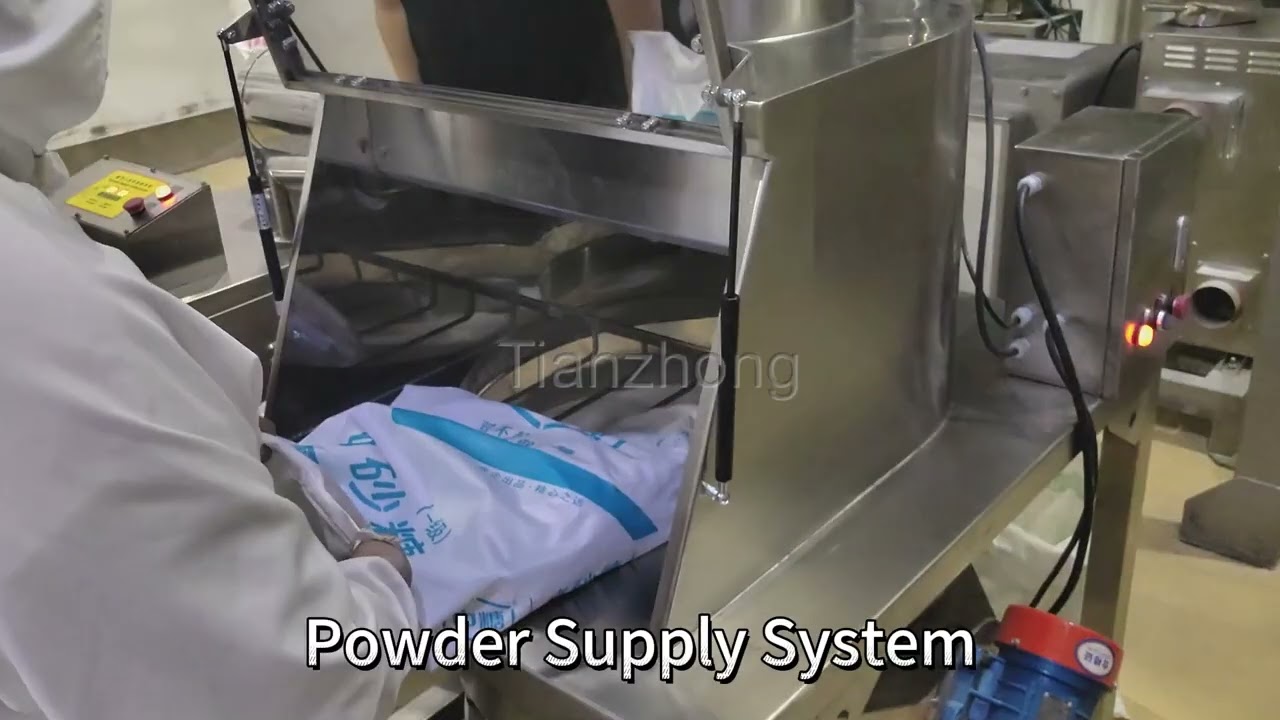

In the food industry, powdered materials are a common raw material, such as flour, milk powder, coffee powder, starch, sugar powder, yeast powder, grain powder, bran, potato snowflake flour, premix powder, yeast powder, bread crumbs, salt, monosodium glutamate, etc. These powdered materials require precise measurement and supply during the production process to ensure product quality and efficiency. However, traditional powder supply methods often have some issues.

High labour costs; traditional production methods require significant manual labour for repeated loading, unloading, transporting, and dispensing of raw materials. As labour costs rise, this inevitably increases labour costs;

Raw materials are prone to contamination, and hygiene and safety are not guaranteed; in traditional powder supply processes, during material dispensing and transportation, powdered materials are easily affected by external environmental factors, leading to contamination, and product hygiene and safety cannot be guaranteed. Batch consistency is unstable, affecting product uniformity; manual batching relies on worker discretion, leading to inconsistent batches and potential errors or omissions, thereby impacting product quality.

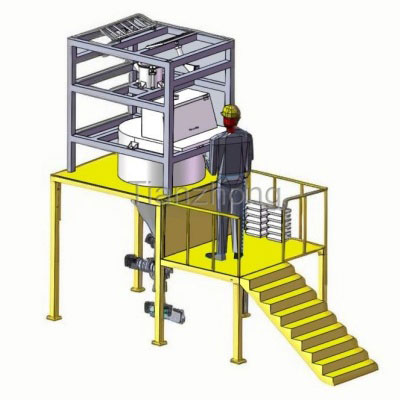

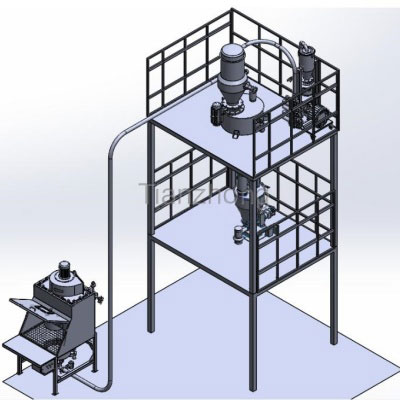

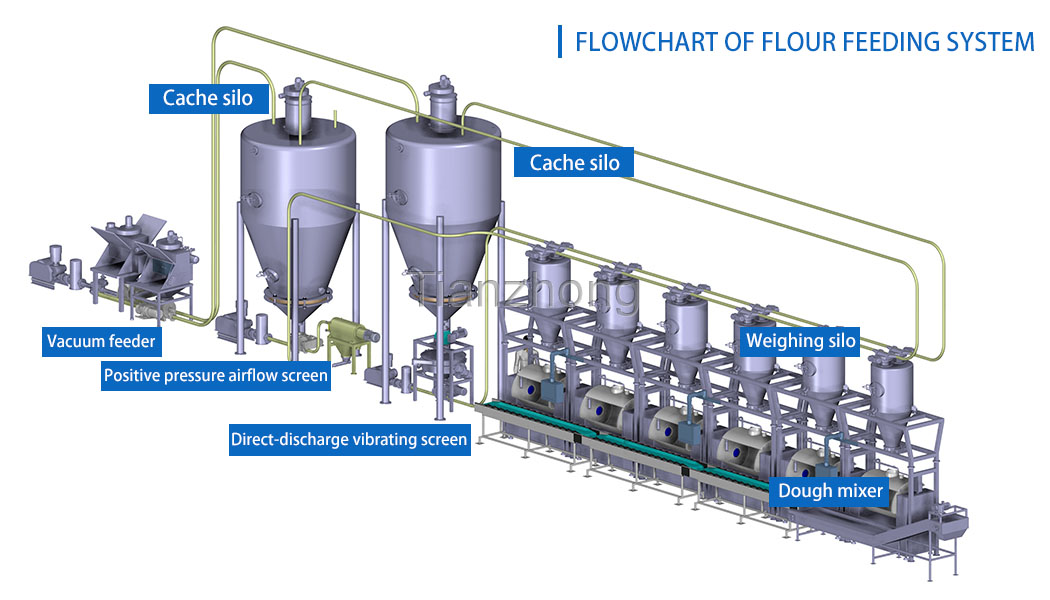

These issues result in unstable product quality, low production efficiency, and increased production costs. The powder supply system consists of a feeding system, storage system, screening system, drying system, iron removal system, metering system, and mixing system;