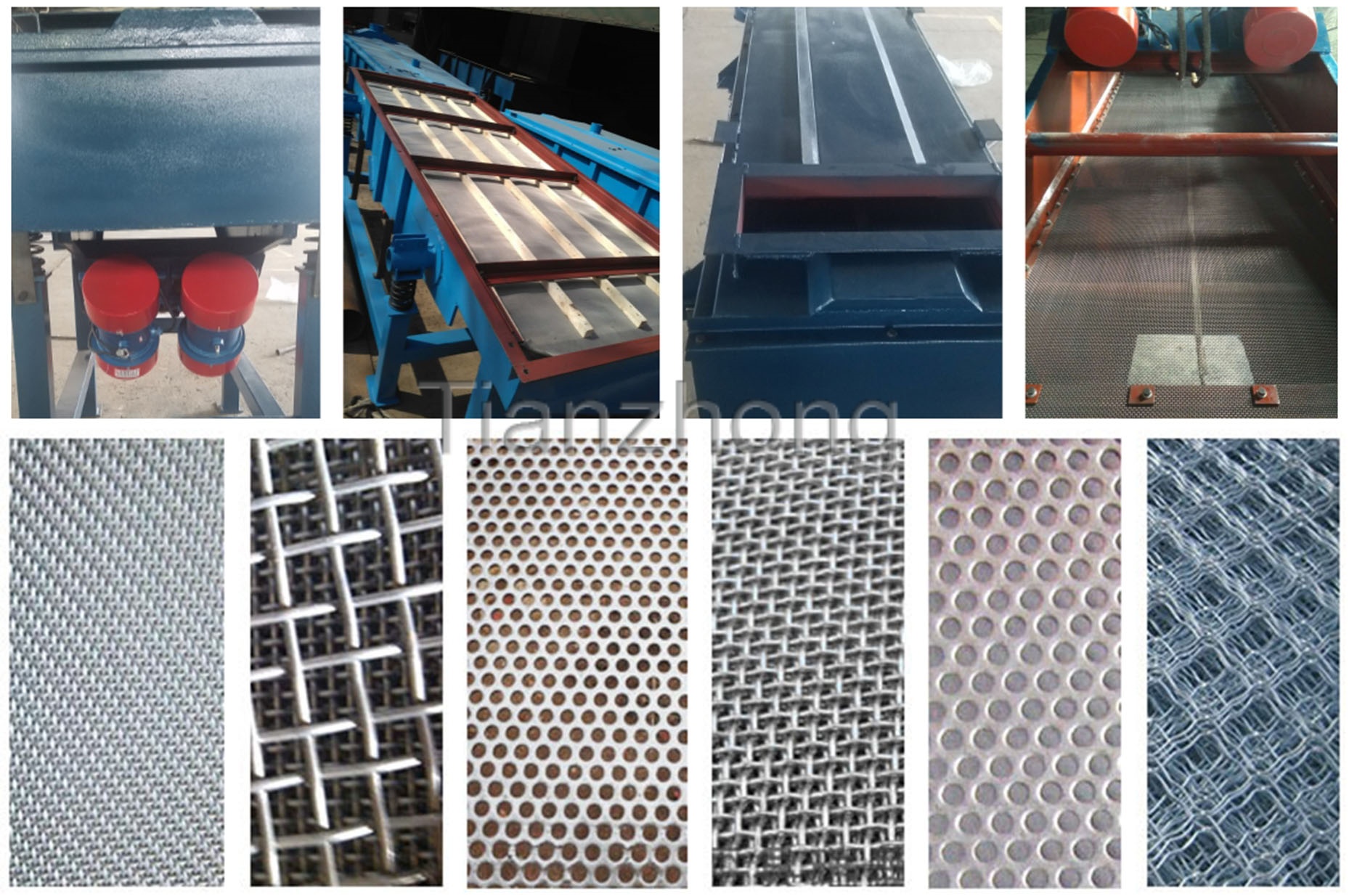

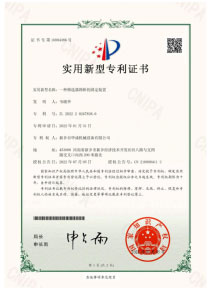

The linear vibrating screen utilizes the principle of vibration motor excitation to cause the material to be thrown up on the screen surface while moving forward in a straight line. Combined with appropriately matched screens, this achieves the purpose of screening.The material enters the feeding port of the screening machine uniformly from the feeding machine, and several types of products and unqualified screened and undersized materials are discharged from their respective outlets through multiple layers of screening screens. Can be used to achieve automated operations in assembly lines. It has the characteristics of low energy consumption, high efficiency, simple structure, easy maintenance, and fully enclosed structure without dust pollution.