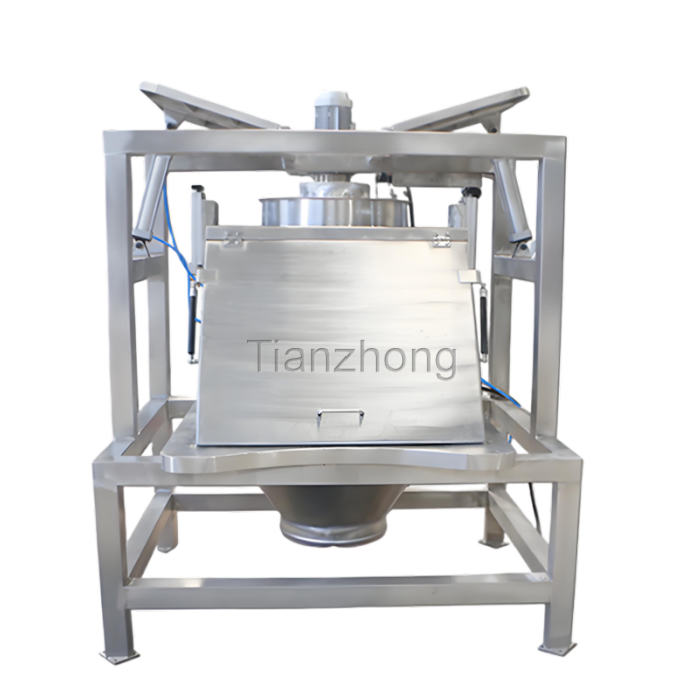

The ton bag feeding station (bag opening station) is an integrated device designed specifically for the automated feeding of powdered materials. Through intelligent control and modular structure, it achieves efficient unpacking, dust control, and precise conveying of ton bag materials, making it suitable for raw material processing in industries such as lithium batteries, chemicals, pharmaceuticals, and food. Its core objective is to address the pain points of low efficiency, severe dust pollution, and high material residue rates associated with traditional manual unpacking, while also meeting the production requirements for high cleanliness and safety.

Definition and Functionality

The ton bag feeding station uses mechanical or automated methods to unpack, unload, and subsequently convey ton bag materials, and is suitable for handling powdery, granular, and small block materials. Its core functions include:

Unpacking and unloading: Guide the materials in the ton bag into downstream equipment using gravity or auxiliary devices (such as vibration or tapping).

Dust Control: Minimising dust leakage through sealed structures and dust collection systems (e.g., baghouse dust collectors) to improve the working environment.

Automated Operation: Supporting manual or fully automated modes to enhance efficiency and reduce human intervention.

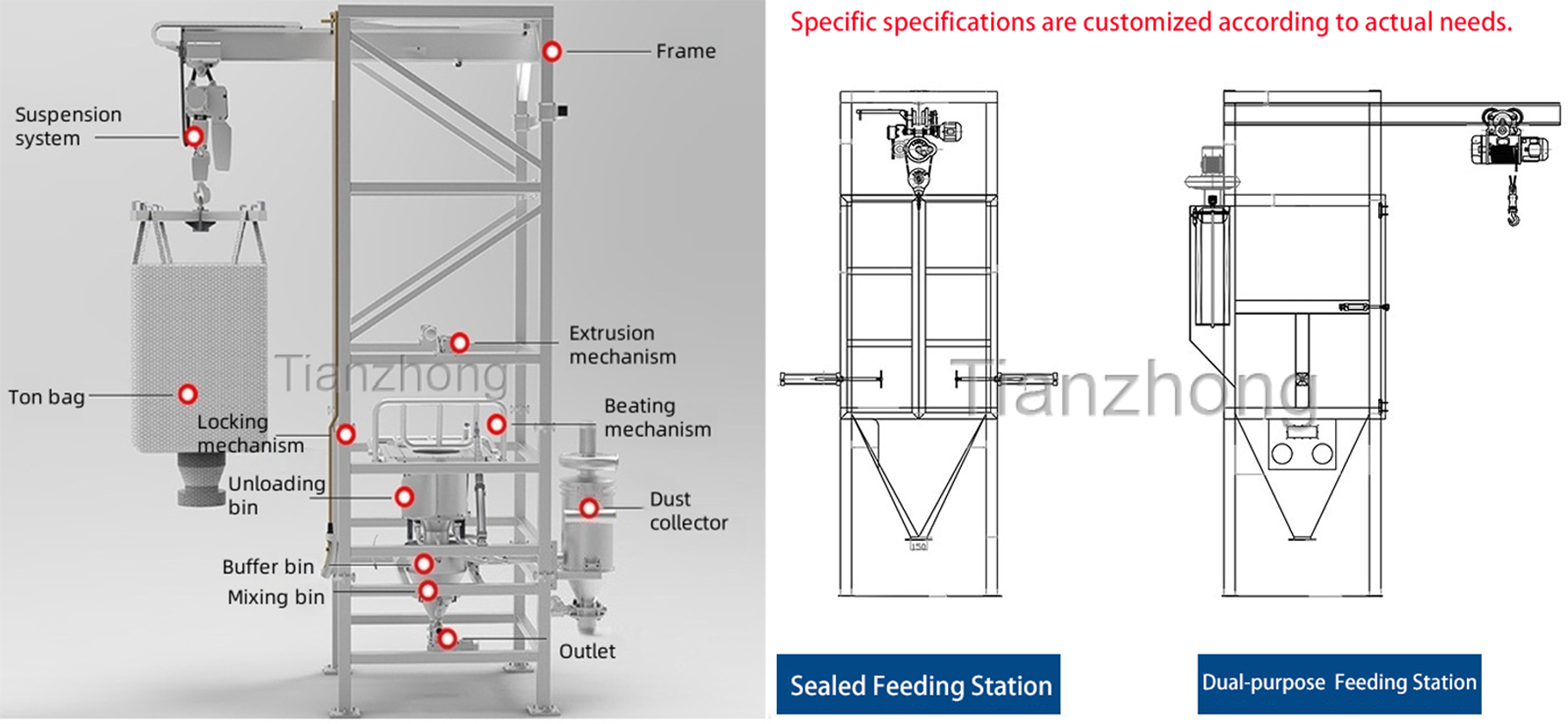

Main Components

A ton bag feeding station typically consists of the following modules:

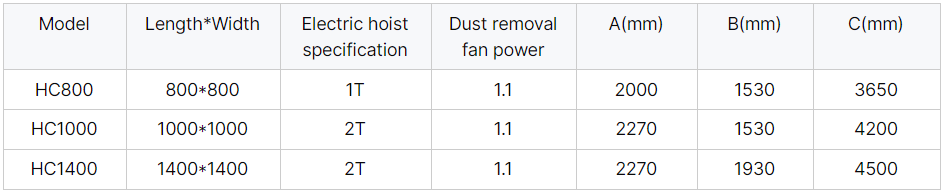

Lifting device: electric hoist, forklift, or overhead crane, used to lift the ton bag to the unpacking station.

Unpacking mechanism: bag clamping device, cutting knife, or manual bag opening tool, used to open the discharge port of the ton bag.

Auxiliary equipment: beating rods, vibrators (to break material bridges), crushers (to process clumped material), and magnetic separators (to remove foreign objects).

Dust collection system: baghouse dust collectors and pulse jet cleaning devices to ensure efficient dust recovery.

Conveying equipment: screw conveyors, tube chain conveyors, pneumatic conveying systems, etc., to transport material to the next process.