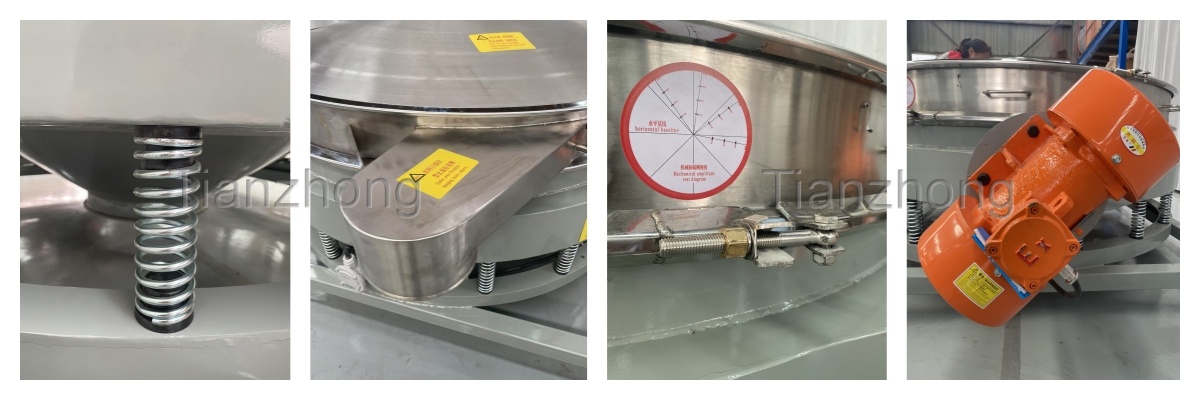

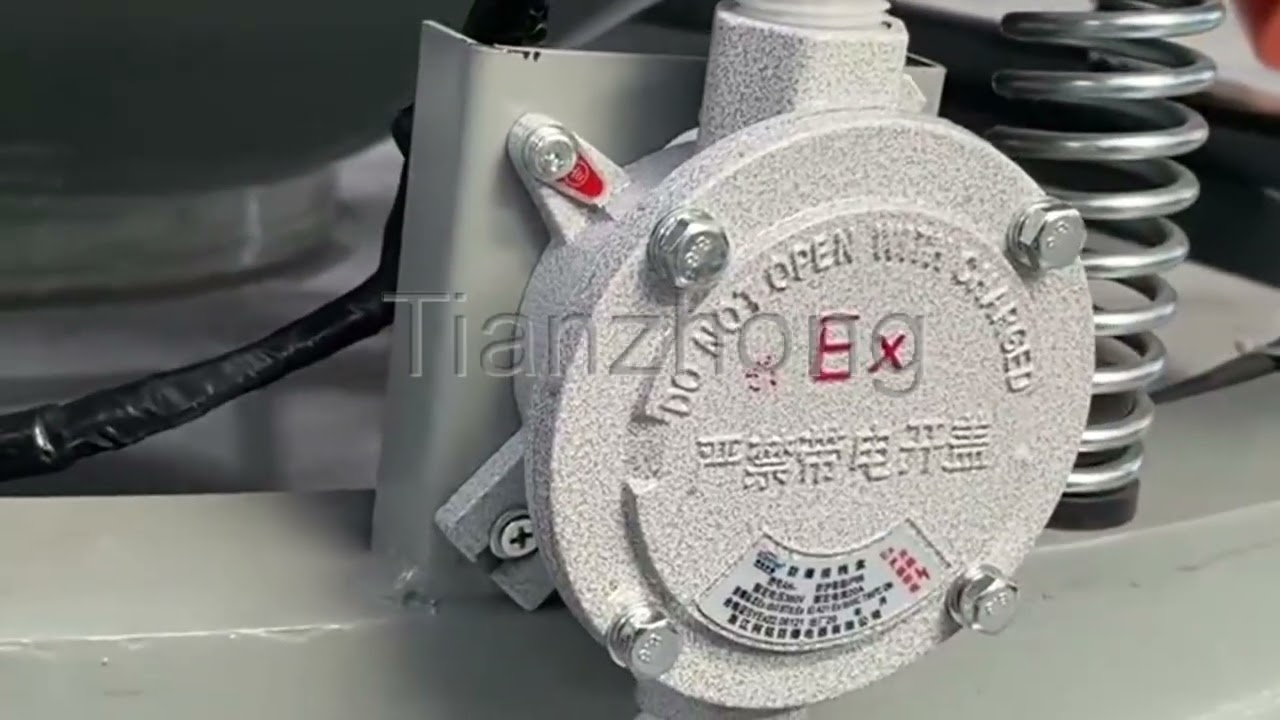

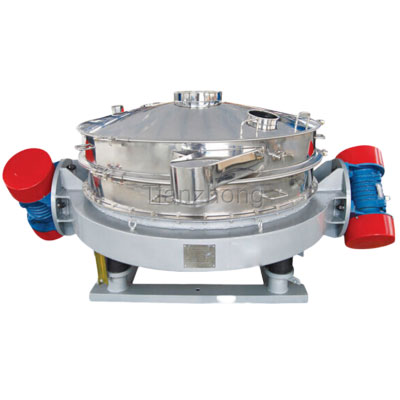

Direct-discharge vibrating screen uses a single horizontal vibrating motor as the vibrating source, with the vibrating motor located on one side of the machine body. After entering the equipment, the material undergoes elliptical motion on the screen surface due to the force of the vibrating source. While rapidly and repeatedly completing the screening process, the vibrating force continuously and repeatedly exerts peeling, dispersing, and reorganisation effects on the material, enabling it to pass through the screen quickly. Material that cannot pass through the screen is discharged through the upper discharge port of the equipment according to its movement trajectory, completing the screening process.

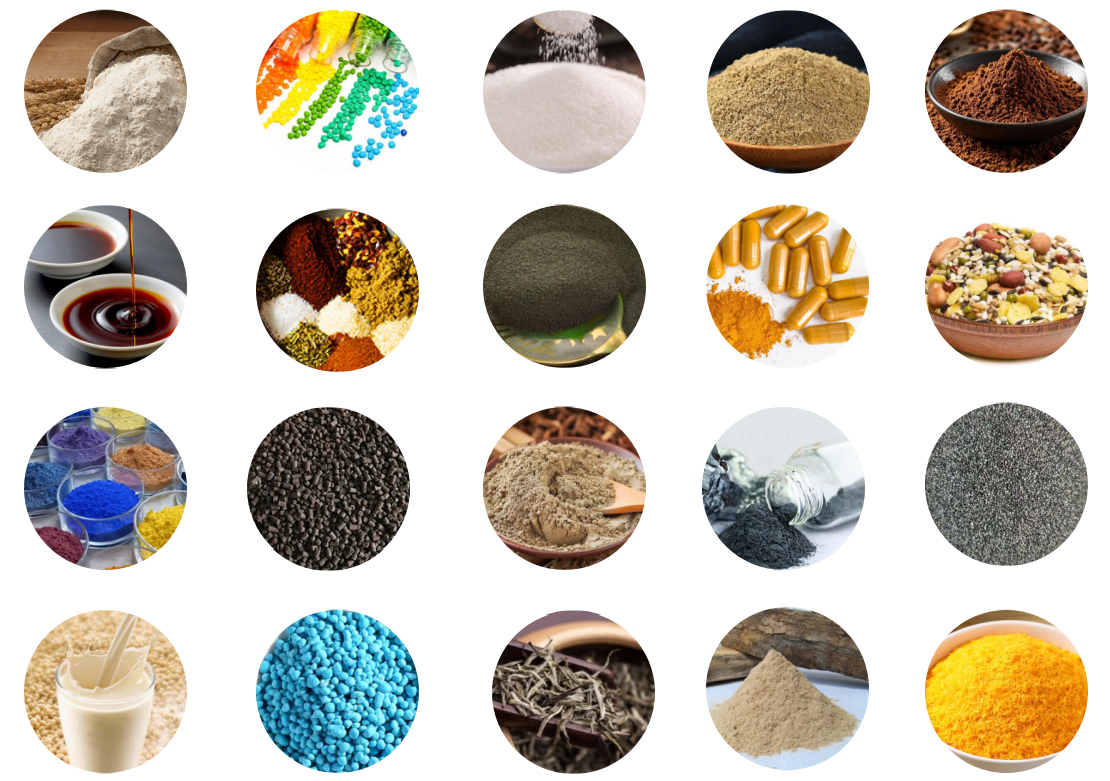

The vibration source is available in single-motor and dual-motor configurations, with multiple adjustable material movement trajectories, significantly enhancing the equipment’s adaptability; direct material discharge enables higher processing capacity. It is widely used for coarse and precise screening of granular powders in industries such as flour, starch, laundry powder, metal powder, additives, chemicals, and non-metallic minerals, featuring high processing capacity and ease of integration with production lines. The screen size can be selected between 600 mm and 1800 mm.