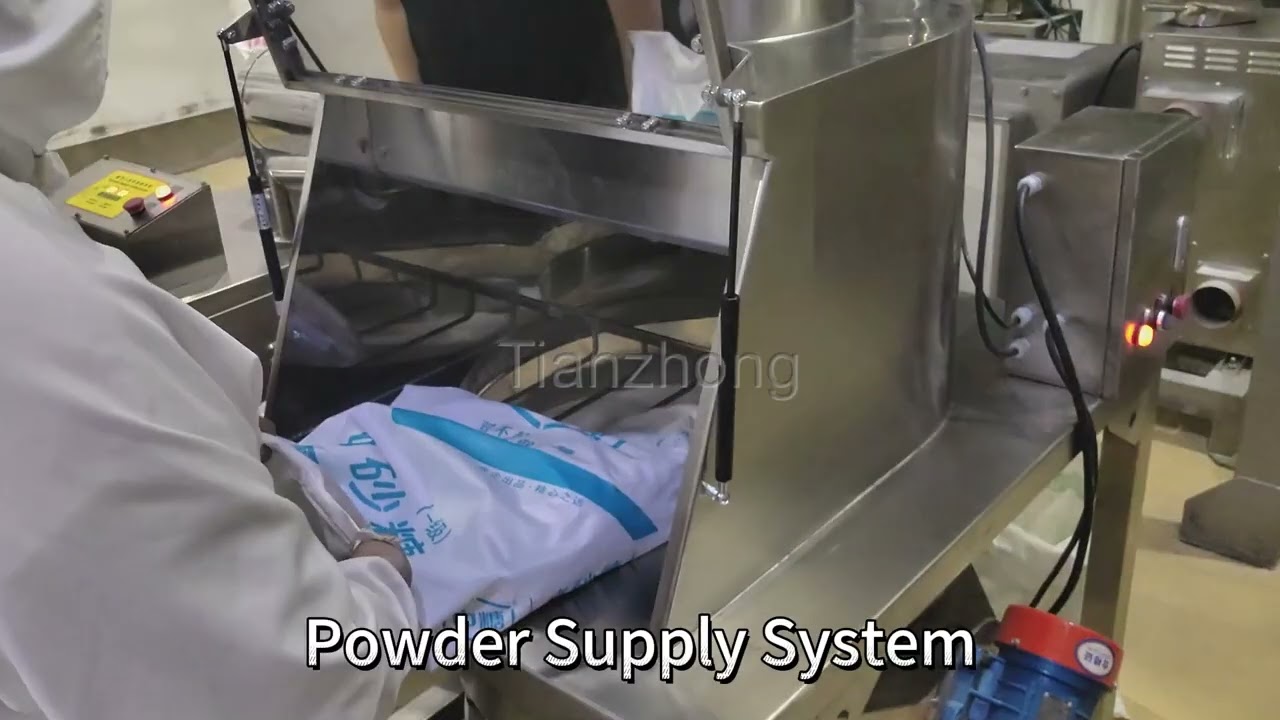

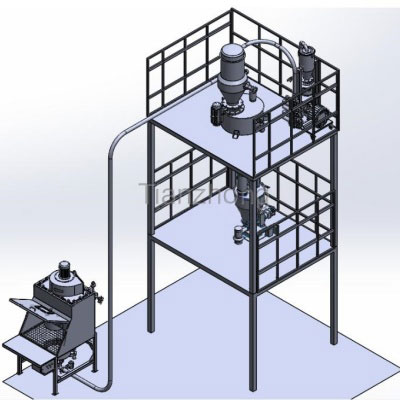

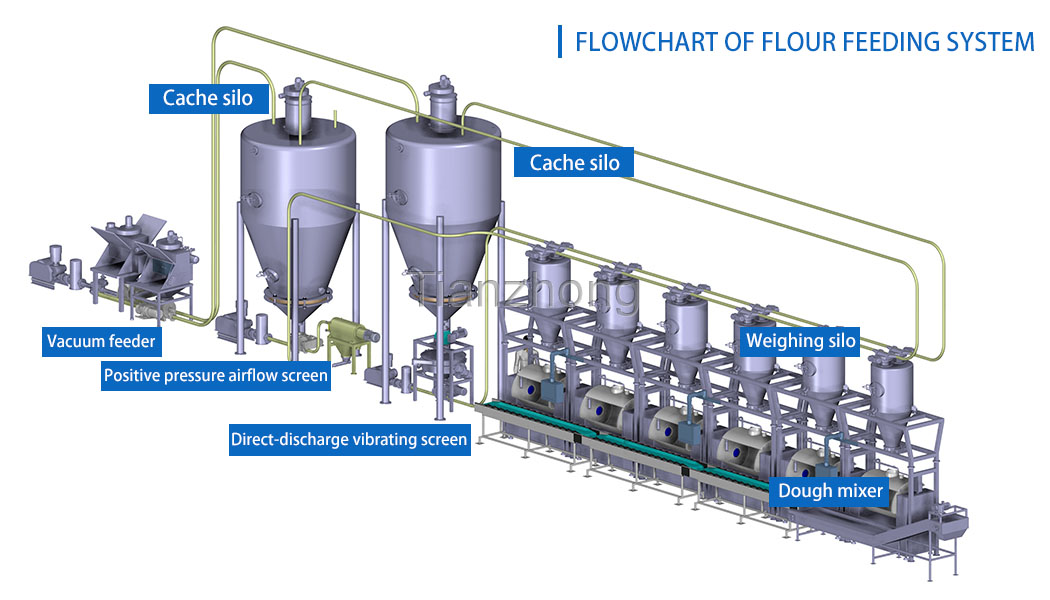

The negative pressure conveying and powder supply system for bread factories is an automated conveying device designed specifically for powdered raw materials (such as flour, starch, wholemeal flour, etc.) used in bread production. It uses a negative pressure (vacuum) environment to achieve efficient and clean conveying of powdered materials in closed pipes. It is widely used in the entire process from raw material storage to transfer to processing (such as kneading and mixing) and is one of the important auxiliary systems for large-scale, standardised production in modern bread factories.