×

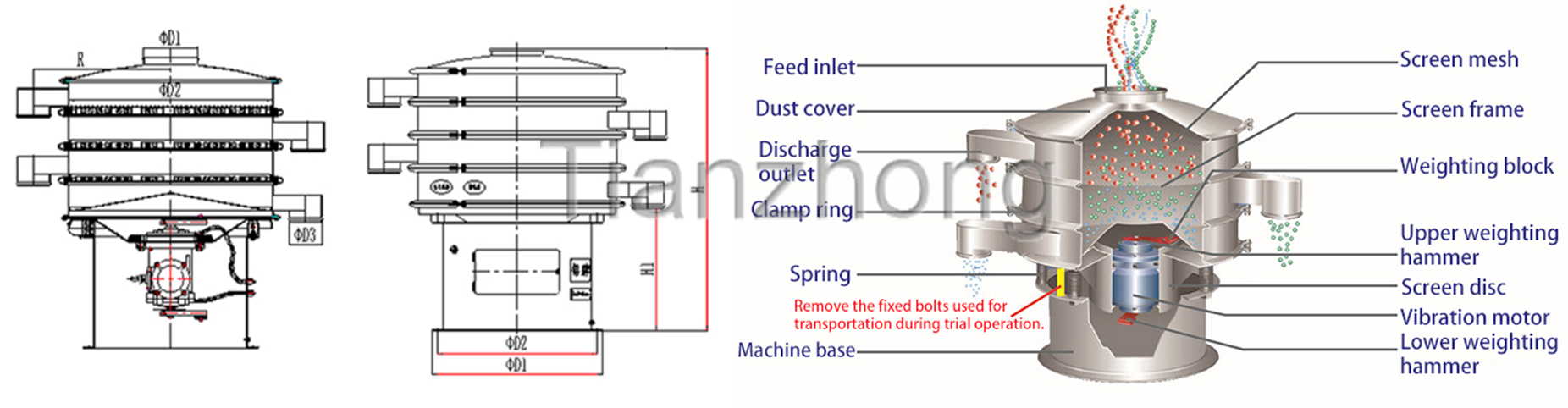

The all-carbon steel rotary vibrating screen is a high-precision screening device that uses a vertical vibrating motor as its vibration source. It achieves efficient material classification through three-dimensional rotational vibration (a combination of horizontal, vertical, and inclined movements). Its unique motion trajectory causes the material to spread in a spiral pattern on the screen surface, significantly improving screening efficiency and accuracy. It is particularly suitable for the screening, impurity removal, and classification of fine powders and granular materials.

It can achieve high-precision screening, easily handling powder materials of 500 mesh or even finer, with a screening accuracy of over 95%.

The unique vibration design keeps the material suspended at all times, increasing its flowability and mesh permeability, and significantly improving screening efficiency.

Utilising high-frequency ultrasonic vibrations, this effectively prevents screen clogging, maintains mesh size, and extends screen service life.

The design is ingenious, making it easy to change the screen and clean, enabling 24-hour continuous operation and reducing production costs.

The flexible design is suitable for a variety of uses.

The all-carbon steel rotary vibrating screen uses a vertical motor as the vibration source. Eccentric weights are installed at both ends of the motor, converting the motor’s rotational motion into three-dimensional motion in horizontal, vertical, and inclined directions. This motion is then transmitted to the screen surface, causing the material to move in an outward-expanding involute motion on the screen. By adjusting the phase angles at both ends, the motion trajectory of the material on the screen surface can be altered.

Wide range of applications: Widely used in the chemical, pharmaceutical, food, metal, metallurgical mining, and pollution control industries.

We are a high-tech enterprise specializing in the research, development and production of vibrating screening, conveying and lifting, crushing and mixing equipment, with products including but not limited to:

●Vacuum Feeder

●Small Bag Dust-free Feeding Station

●Ton Bag Feeding Station

●Powder Supply System

●Circular Swing Screen Series

●Vibrating Screen

We support customized production to meet the special needs of different industries.

Of course, we will design according to customer requirements.

5-10 working days for conventional products.

We have a large factory in Xinxiang, China, covering an area of 12,000 square meters. Welcome to visit!

We usually accept T/T, L/C,T/T: 30% in advance as down payment, the balance before delivery.

We provide 1-2 years warranty (depending on the model), after-sales team responds within 24 hours, support remote guidance or on-site repair.