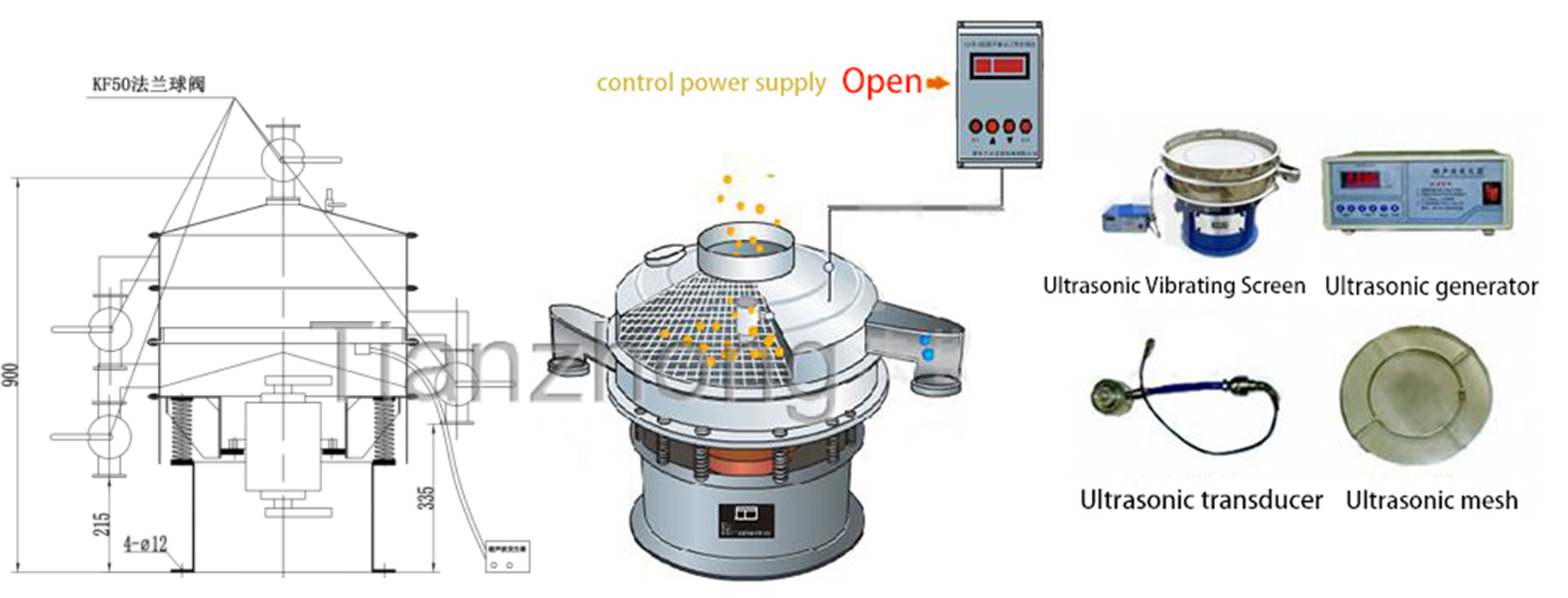

The vacuum-sealed screening machine(3D-printed titanium alloy ultrasonic vibrating screen) is a high-precision fine powder screening device featuring low noise, high efficiency, and a fully vacuum-sealed structure. It is suitable for screening materials like 3D printing powders that cannot come into contact with oxygen. The 3D-printed titanium alloy ultrasonic vibrating screen utilizes a vertical motor as its vibration source. Eccentric weights mounted at both ends of the motor convert its rotational motion into three-dimensional movement—horizontal, vertical, and inclined—which is then transmitted to the screen surface. Adjusting the phase angle at both ends alters the material’s trajectory on the screen. Simultaneously equipped with a high-strength external ultrasonic system, it features high screening and filtering precision with minimal mesh clogging. This effectively resolves screening challenges caused by agglomeration, static electricity, and strong adsorption blocking the mesh, significantly improving the first-pass clean rate and overall screening efficiency. It ensures long-term mesh unclogging during the screening process. Production rates can be substantially increased based on material particle structure. This ensures long-term high-efficiency screening while extending screen mesh lifespan. The equipment includes a reserved inert gas inlet for connecting inert gas to protect materials!